casainho

10 GW

- Joined

- Feb 14, 2011

- Messages

- 6,045

I am being trying to write down a list of potential things we would win if developing our own motor firmware. For now, it is:

1. Customize assist levels: original firmware lowest level 1 is to much powerful for my needs.

2. Improve Walk Assist: original Walk Assist rotates the wheel at 1 or 2 km/h, which is VERY slow, rendering this feature useless.

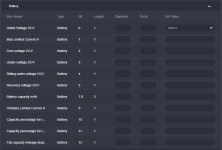

3. Unlimited battery voltage range: choose between 24V / 7S up to 52V / 14S cells batteries.

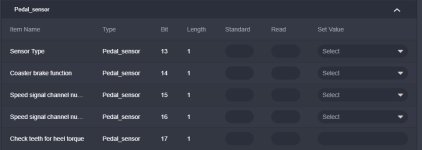

4. Improve (reduce) the lag between applying force to the pedal and the electric assist kicking in.

5. Improve (reduce) the lag between stopping pedaling and the motor continuing assist.

6. Improve / adjust the rate at which assist is 'ramped up' / 'ramped down'. In some cases, it seems like assist kicks in too hard, moves the pedal forward faster than my leg can keep up, then drops off. This makes for a very weird pedaling experience where it feels like you almost fall forward for a second when assist kicks in, only to crash into a 'wall' when the assist suddenly stops again.

----

I went crazy and bought the just launched latest model of Garmin Edge to use on my EBike, because it has the Stamina feature that predicts in real time if I will be able to finish the race while keeping the current pace / power. I am already using the same Stamina feature for running, on my watch. Now Garmin will use both data from my cycling and running activities, and will help to improve even more that prediction and all other fitness metrics as my needed recovery time, stress, etc.

But to have Stamina prediction on cycling, the bicycle need to have a power meter. Unfortunately, as we found that Bafang M500/M600 torque sensor saturates at 40 kgs weight on the pedals, I do not think it will be good to use as input to Garmin Edge - still I wish to develop and try it later. So, I decided to also buy the Garmin XC200 power meter pedals. Later I can also use this pedals to calibrate a possible power value calculated by Bafang M500/M600 torque sensor, even if will have limitations.

And I want more and more the Bafang M500/M600 EBike to have the ANT+ LEV EBike wireless standard, to integrate on the Garmin Edge my EBike, being able to see there the current assist level, battery SOC and current motor power, and change the display page from the remote.

1. Customize assist levels: original firmware lowest level 1 is to much powerful for my needs.

2. Improve Walk Assist: original Walk Assist rotates the wheel at 1 or 2 km/h, which is VERY slow, rendering this feature useless.

3. Unlimited battery voltage range: choose between 24V / 7S up to 52V / 14S cells batteries.

4. Improve (reduce) the lag between applying force to the pedal and the electric assist kicking in.

5. Improve (reduce) the lag between stopping pedaling and the motor continuing assist.

6. Improve / adjust the rate at which assist is 'ramped up' / 'ramped down'. In some cases, it seems like assist kicks in too hard, moves the pedal forward faster than my leg can keep up, then drops off. This makes for a very weird pedaling experience where it feels like you almost fall forward for a second when assist kicks in, only to crash into a 'wall' when the assist suddenly stops again.

----

I went crazy and bought the just launched latest model of Garmin Edge to use on my EBike, because it has the Stamina feature that predicts in real time if I will be able to finish the race while keeping the current pace / power. I am already using the same Stamina feature for running, on my watch. Now Garmin will use both data from my cycling and running activities, and will help to improve even more that prediction and all other fitness metrics as my needed recovery time, stress, etc.

But to have Stamina prediction on cycling, the bicycle need to have a power meter. Unfortunately, as we found that Bafang M500/M600 torque sensor saturates at 40 kgs weight on the pedals, I do not think it will be good to use as input to Garmin Edge - still I wish to develop and try it later. So, I decided to also buy the Garmin XC200 power meter pedals. Later I can also use this pedals to calibrate a possible power value calculated by Bafang M500/M600 torque sensor, even if will have limitations.

And I want more and more the Bafang M500/M600 EBike to have the ANT+ LEV EBike wireless standard, to integrate on the Garmin Edge my EBike, being able to see there the current assist level, battery SOC and current motor power, and change the display page from the remote.