JackFlorey said:

You can always balance any pack with enough balancing power.

But that's no indication that 56 individual cells in say a 14s4p pack are within 50mV of each other even if the parallel groups appear healthy (within 50mV of each other).

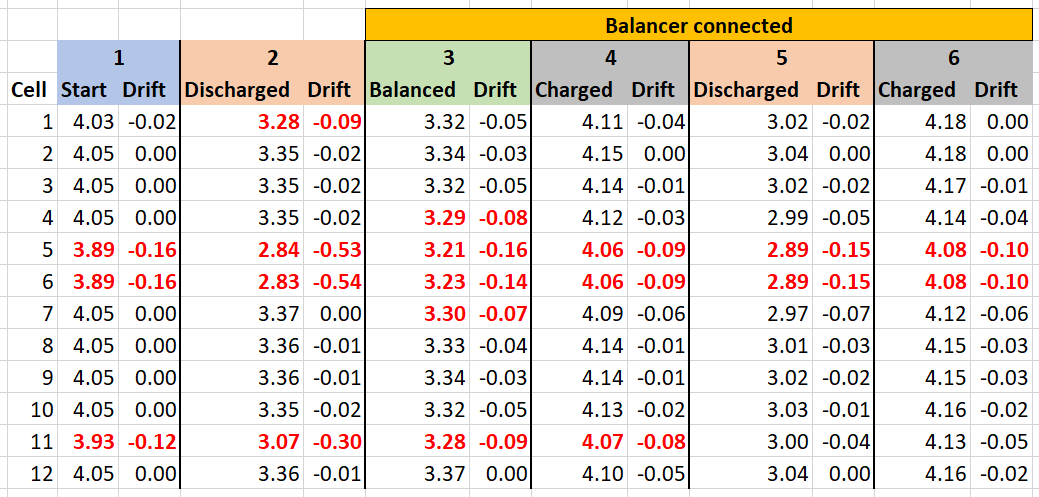

The downside of a spot-welded pack is that the parallel group voltages do not represent the actual health of each cell in the parallel groups. In the following chart the actual health of the 2s3p cell at 3.43v would be hidden in a spot-welded pack as only p-group voltage can be easily checked after relaxing voltage rest. Individual cell health can't be easily checked in a spot-welded pack.

To determine which cell in a suspect p-group is bad you need to check the resting voltage of each cell in the p-group instead of waiting until the hidden bad cell (spot-welded pack scenario) is so bad that the BMS shuts down the entire pack. I don't use a BMS as i bottom balance the p-groups within 10mV of each other before bulk charging at 1.5A rate.

The following individual cell voltages are after resting the pack for 14 days (1/1/21 to 1/15/21). Nine cells were replaced with new 30Q6 KH1T cells. The 141 cell at

3.73v wasn't replaced. After 125 more cycles in 2021 (250 total), 4 more

141 cells need to be replaced (see other 141/K chart below this one) including the

3.73v cell) (

141 in bold red) ... ...

JackFlorey said:

But you end up doing a lot of work (=inefficiency) once you get major imbalances.

The worst cell in the above 30Q 10s3p pack is 2s3p at only 3.43v needing to be replaced before it demotes the entire p-group and finally triggering the BMS to shut-down the pack.

So far after 125 cycles all of the 9 new 30Q6 KH1T were OK after being tested this month. However, 4 more of the 141 cells (after another 125 cycles in 2021) need to be replaced (

red) ...

141--141--141--141--141.......141--

141--141--141--141

.K.....K.....K....K....141........K.....K.....K.....K.....K

141--141--141--141--

141.......

141--141--

141--141--141

Thus the downside of a spotwelded pack; whereas

APL's Pressure Contact Battery box ... https://endless-sphere.com/forums/viewtopic.php?f=14&t=113512 ... as well as other non-spotwelded designs permit individual cell testing after so many c/d cycles thus preventing a worse case scenario. This feature testing individual cells is crucial with Grade B cells, salvaged cells and high energy dense cells with 30Q apparently more prone to self-discharge.

Unlike goatman i've had little success in atempting to **regenerate** the nine cells replaced in January of 2021 or 4 more

141 cells that will need to be replaced before March.

Bottomline: Using my AstroFlight Blinky Balancer or my "cheap" 5s Active Balancer Board (IMO) doesn't **regenerate** an unhealthy cell it just prolongs its inevitable demise.