wish I had more ambition ?

I have always lacked ambition,

Now it is snowing and the roads are shot.

I dropped off the hub motor two days ago and was supposed to return with those horse shoe shaped washers that comes with torque arms so they can true the wheel after they lace it to a new rim.

I also need to go to Home Depot for lumber and hardware. I can't mount anything without that stuff. The 36V - 1,000W motor is sitting out in the van still in the box. I also have the 89 tooth #25 sprocket. I picked it up at the post office yesterday.

I would have done something earlier but when I got up to get a drink of water around 3 PM it was snowing and the roads were shot so went back to bed until 5 PM.

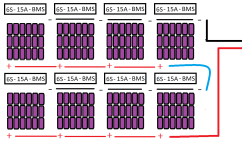

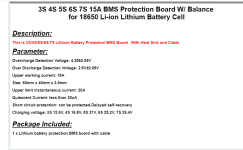

My wife made coffee and the news is on and am sitting here wishing I had something to do. No soldering iron and did not get around to ordering those 18650 cells DA posted. DAN said the BMSs I posted were junk and DA did not post a link for a decent 6S BMS.

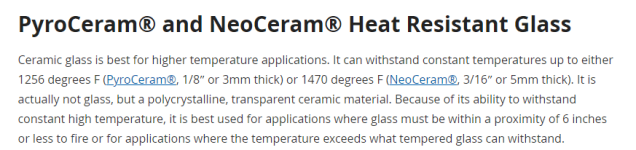

Usually like 95 times out of 100 or more when I think of something someone else has already done it . It just makes sense that if nobody has built a smoke free LiPo box to trap most or all the toxic gasses from a LiPo fire that the idea just might receive a patent. It also just so happens that I used to build fish tanks and glass in general is flame resistant however at a high temperature it can melt. That is why fiberglass under the metal cash box could prevent the metal from melting the glass. But using fireproof glass is an even better idea.

I have a 45 gallon aquarium and was thinking about putting some fiberglass insulation under the cash box and an air purifier inside however it is not practical as who is going to put a 45 gallon aquarium on the back of a bike, Also it is in a confined space and not near any window or ventilation to get the toxic gas out of the house that the air purifier cant filter out.

It just makes sense to have a portable container for both running and charging. something that can keep the flames under control and filter out all that smoke and toxic gasses. It would help out the environment on a small scale but on a large scale help the immediate surrounding environment when someone might be close enough to breath in some of those toxic fumes. After all a great percentage of people who die in fires do so from breathing in the smoke.

However I guess nobody wants to pursue my great idea any further and my lack of ambition may just doom the invention to fail. I hope not. I will also keep researching to see if anyone else has attempted such a thing. I can't be the only person to think of it.

OK. I get it. They already have a lot of LiPo boxes they sell to release smoke and contain the fire and for 60 bucks it would be difficult to compete with that.

HOWEVER

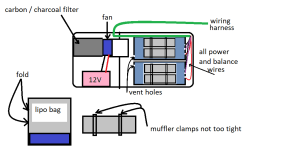

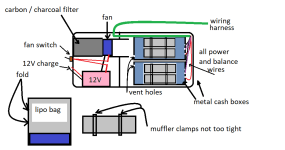

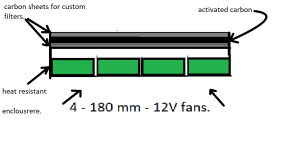

here is a great DIY idea that would take it to the next level. It just so happens I have back ground experience in building active charcoal filters for my hydroponic systems I was running back in upstate NY. a few years back. I have a medical state issue cannabis card here so wont be doing hydroponics until I move in a larger apartment and recreational is legal and ok to grow here.

The diagrams and links will work however am not sure what the temperature is where the smoke comes out of these bat boxes or fire proof LiPo containers. Once that is established though it would be really straight forward how to build the filter. There could be a plastic container the right dimensions or may have to construct one out of a material. Wall-Mart used to sell activated carbon for their aquarium filter packs they used to sell and you add the carbon to them. Not sure anymore as not looked lately. I got the sheets of carbon from Home Depot which were to replace filters in air purifiers.

Obviously the first step is ordering the Bat box or similar enclosure and then measure the width and length of the top where the smoke comes out and then go from there. I plan on building my own after I order a Bat box. I already have bullet extensions and a link to order two foot balance connecter wires.

https://www.ebay.com/itm/1-JST-XH-6S-Balance-Wire-Extension-Adapter-with-60CM-24inches-22awg-Wire/331562025770?_trkparms=aid%3D1110006%26algo%3DHOMESPLICE.SIM%26ao%3D1%26asc%3D20201210111314%26meid%3D23c882747b2b4ceebc4fa06baab44295%26pid%3D101195%26rk%3D5%26rkt%3D12%26mehot%3Dsb%26sd%3D162529280314%26itm%3D331562025770%26pmt%3D1%26noa%3D0%26pg%3D2047675%26algv%3DSimplAMLv5PairwiseWebWithDarwoV3BBEV2b%26brand%3DTurnigy&_trksid=p2047675.c101195.m1851

I will probably test my filter by drooping a smoke bomb inside the box and quickly closing the lid and turning the fans on with a switch hooked to a 12V battery. After that I will run the old LiPo packs awhile and eventually order new hard shell Multistars to replace them.

It just happens that I already own four 160mm or 180mm 12V fans I took out of an old server I took apart back when I scrapped metal. That will save me some money.

https://www.getfpv.com/pulse-lipo-lithium-battery-charging-safe-box.html?afid=aVlOV0hBdmd6THc9&gclid=CjwKCAiA_eb-BRB2EiwAGBnXXmZtS1s6EgOTK3uwLj4O3jcepEmjqIZr3a9gAZ52FFGpQ9gpIrkDORoCzNgQAvD_BwE

300mm by 220 mm is roughly 9 by 12. 9 by 12 inches is just a little larger then the top of the box which is ok as will sit on top so smaller wont work but a fraction of an inch larger is ok as four fans are pulling the smoke up thru the filtration.

It is possible then to build a filter awhile the box is being shipped.

this really sucks. I got the winter blues.

Thanks.

LC. out