Yeah, you need the control LED display and the breakout cable I posted.

If you meter the pinout you should be able to cut and splice future displays to controllers.

There has to be a control module which just plugs in the controller. I doubt they make a controller that requires cutting and splicing. I am sick of cutting and splicing. I had to do it with the throttle. The only way I would cut and splice is if I know it could work like the power lock on a brush controller. It is two wires twisted together with a piece of tape over it or a paper clip to the two holes on the little white plug.

I need to find the correct module that will plug in. It could be the one in the picture in my last post. The picture of the plug is round and looks like the one but only shows two pins. There could be more but no way to tell with that picture.

I will look on e bay for cheaper controllers and modules.

https://www.ebay.com/itm/48V-36V-17A-Controller-For-250W-350W-Brushless-Motor-Ebike-Electric-Bicycle/353290930607?_trkparms=aid%3D1110006%26algo%3DHOMESPLICE.SIM%26ao%3D1%26asc%3D20200520130048%26meid%3D9f847f59f6204a928fc39ed22bace380%26pid%3D100005%26rk%3D12%26rkt%3D12%26mehot%3Dlo%26sd%3D164322481824%26itm%3D353290930607%26pmt%3D1%26noa%3D0%26pg%3D2047675%26algv%3DSimplAMLv5PairwiseWebWithDarwoV3BBEV2b%26brand%3DUnbranded%2FGeneric&_trksid=p2047675.c100005.m1851

https://www.ebay.com/itm/KT-LCD3-Display-Electric-Wheel-24V-36V-48V-Intelligent-E-Bike-Panel/332849482230?hash=item4d7f6009f6:g:nhMAAOSw2yVbzYM7

That has the 9 pin plug for the motor and does not require a special throttle with a yellow round plug and that is the module for it. Thing is though I can not return the e bikeling controller as I cut off the yellow plug on it as the throttle I ordered had the same female plug and not a male so hard wired the throttle. After searching extensively I only see displays with 5 pins and it is stated on the controller I ordered I need an 8 pin. Which no longer exists as far as I know so will probably end up taking a hammer to the controller as I cant return it as I cut the yellow throttle plug off.

I still have a second Bafang motor though so will try to order those and have a 3 and a 4 wire throttle that has standard white plugs but will still need to call the post office Tuesday to see if I can change the shipping address after China ships it as they wont ship to my PO. box and don't need it to get stolen.

However.

I am about to remove the Currie from my little e bike work shop as I failed miserably after about two weeks of working on it. Everything is done so will only take a few minutes to hook up an 8 pin display module if one exists that one in the picture will not work. Or after I speak to someone from e bikeling and see if I can order an 8 pin direct from them. It takes about 5 days to a week to get a module from Amazon , not sure about e bikeling. I was just told that Monday is holiday so cant call e bikeling until Tuesday so I need to stop working on a bike that still needs parts and work on the other bike I have all the parts for.

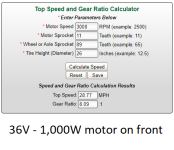

The 26" dual suspension with the 1,000W direct drive hub motor with the new rim and wiring and the 1,000W 36V chain drive brand new motor on the front. 2 kilowatts total and 30 mph gearing @ 48V rear and 36V front. If I ever get around to building 18650 packs and can manage to build a 60V pack for the 1,000W 48V hub motor and a 48V pack for the 36V - 1,000W chain drive I will be looking at 36 to 38 mph easily.

The Currie is only a 20 mph bike as the 750W gear reduction motor only has 20 mph gearing at 36V and the Bafang motor is a lost cause at this point and will only go about 16 mph. Not something I am interested in wasting any more money on. I might just throw both Bafang motors in the dumpster unless I can take them apart and re wire them. If I cut off the 9 pin motor plug there should be three motor wires and 5 sensor wires. Not sure what the #9 pin is even for. Please let me know if that would be my best option. Any brushless controller could work then and why not run a 30 amp controller and 48V. If I could get 22 to 24 mph out of those Bafang motors it would be worth buying more.

Please let me know as before I toss them in the dumpster I am thinking about re wiring it. I succeeded with the direct drive and had to take that motor apart. This one I should only have to cut the 9 pin plug off and I should have access to 3 motor and 5 sensor wires. I would have done so in the first place if I knew there was no 8 pin display. I would never have wasted 50 bucks on a useless controller as I have a 500 watt brushless controller Dan sent I never used.

Please let me know.

Thanks.

LC. out.

PS. I need to go to the beer store but found this.

https://endless-sphere.com/forums/viewtopic.php?t=81213

When I get back I will call green dot and see how much is on the card and order two 9 pin extension cables and then go from there that way I wont have to cut the motor wire to splice into a different controller. I need to finish reading that forum topic also. It is worth it to me as most of the time in the city I only go 10 to 15 mph and I usually have a second rear motor capable of > 20 mph when I need it.