latecurtis

100 MW

Yea. Thanks.

That will put me on the right track.

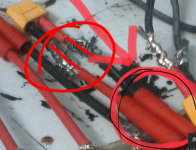

The 9 pin cable coming from the motor and controller are both way too short. It is why I had to extend the controller down and now is in the way of the fork when turning right. I need about an inch more so am about to slide the rack back a little.

As far as the throttle It brings me back a few years when my friend Eric back in NY was stripping the gold pins from old computer parts for the gold plating. He was separating them according to the amount of gold. If I can find the correct size pins and then tape the female connecters together it would work.

I am ordering the 9 pin extensions on Amazon for 12 bucks I can mount the controller where I originally wanted to about 6 inches higher, It will give me extra length for the throttle.

I just hope to find the pins. small solid copper wire is what I am searching for now. Some very thick 8 gauge cable sometimes has that and it is brittle and easy to break off.

frock it !!!!

Sick and tired of setbacks on this build. I have been as patient as possible for me and now it will either work or it wont. No instructions came with the controller and no on and off switch so am wondering if it will even work if one of those other plugs is required to turn it off and on.

I might end up cutting more plugs off and splicing wires together before I am finished. does anyone have a clue. I went to e bikeling web site and did not find a wiring diagram or anything on the controller. I will try Bafang. Hopefully it is not all in Chinese. If it don't work today The motor , controller and throttle will find a new home in the garbage dumpster.

Thanks.

LC. out.

That will put me on the right track.

The 9 pin cable coming from the motor and controller are both way too short. It is why I had to extend the controller down and now is in the way of the fork when turning right. I need about an inch more so am about to slide the rack back a little.

As far as the throttle It brings me back a few years when my friend Eric back in NY was stripping the gold pins from old computer parts for the gold plating. He was separating them according to the amount of gold. If I can find the correct size pins and then tape the female connecters together it would work.

I am ordering the 9 pin extensions on Amazon for 12 bucks I can mount the controller where I originally wanted to about 6 inches higher, It will give me extra length for the throttle.

I just hope to find the pins. small solid copper wire is what I am searching for now. Some very thick 8 gauge cable sometimes has that and it is brittle and easy to break off.

frock it !!!!

Sick and tired of setbacks on this build. I have been as patient as possible for me and now it will either work or it wont. No instructions came with the controller and no on and off switch so am wondering if it will even work if one of those other plugs is required to turn it off and on.

I might end up cutting more plugs off and splicing wires together before I am finished. does anyone have a clue. I went to e bikeling web site and did not find a wiring diagram or anything on the controller. I will try Bafang. Hopefully it is not all in Chinese. If it don't work today The motor , controller and throttle will find a new home in the garbage dumpster.

Thanks.

LC. out.