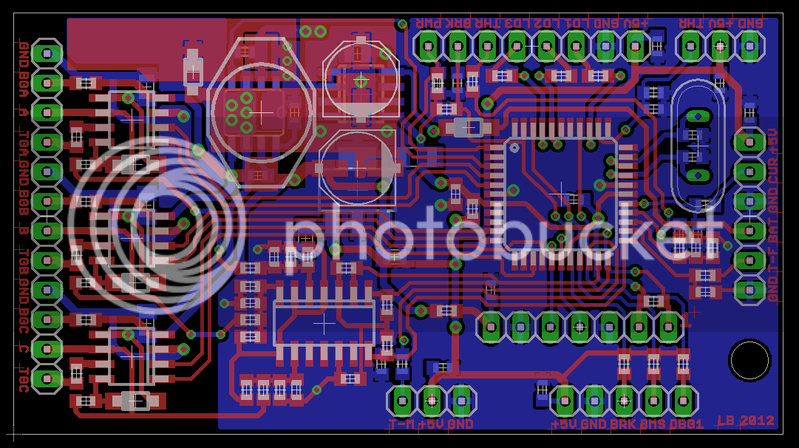

There is many tricks. The system using irfd9110 and irfd110 fets in a buffer stage I use is one of them. One of the biggest tips I can give is keep all traces dealing with feeding power to and from the fet gates as short as possible. Another is I use a diode across one gate resistor followed by another resistor so I have 33ohms on resistance and 3.4 ohms off resistance. You can also find ferrite beads to fit on the gate leg but make sure you measure the ringing and then find a bead with a spec sheet that has a resistance that is higher at that frequency.casainho said:Walls99, what are the capacitors value you use at input of your controller??

I found that the problem I had were the "ringing" on commutation. I changed the resistors from 10R to 100R and got a better system but I ended up to change again to 470R. No I have no problem but rise/fall time is really bad, about 1us!

I wounder is there is a way to get quick rise/fall times but still avoid the ringing problem.

Last but one of the most common tricks is RC snubbers. You can read my powerstage thread and lebowski's IC thread for info on them. As for the use they are a band aid fix they are a fix but at the cost of efficiency and if you design it right you wont need them in the first place. But for guys like lebowski this means a whole new design from scratch! I am going to try to design and redesign to make sure I don't need them. So far ringing is not my problem although I thought it was at 12v but once I upped the voltage it went away.