I am now more fit, I use my ebike with Bafang M500 and I use a gravel bike (a regular bicycle, no motor). I really care about my health and the bicycles / ebikes are strategic health and pleasure machines I use, other than small trail runs and swimming.

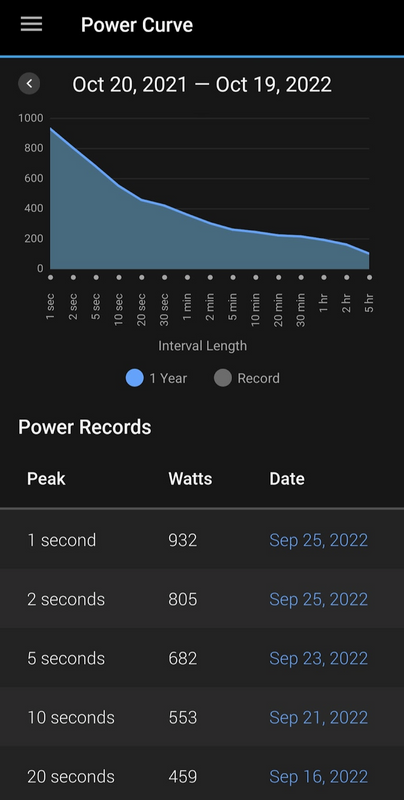

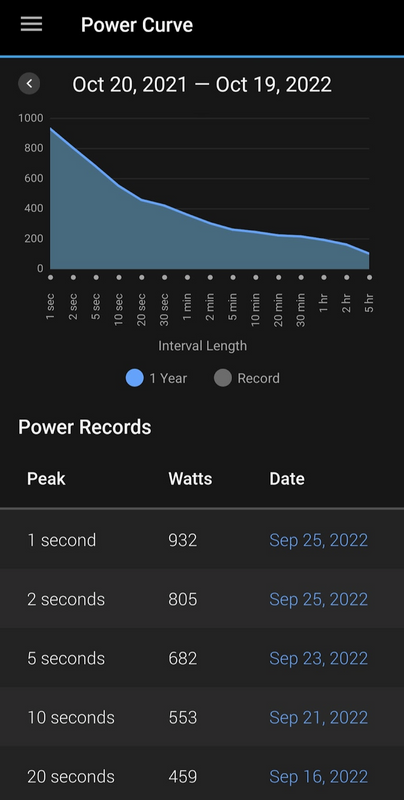

On both bicycles, I have the same Garmin pedals XC100 that measures my pedal power. My average regular pedal power is around 200 watts and I like to pedal at that level on my rides. But I can also give peaks of like 400W for 30 seconds, etc - see my power curve bellow measured by my pedals.

Although I am looking to do fitness, I still need to use the ebike for that step and long hills, on days with 80 kms and that I take like at least 6 hours to do it. This long day rides and this power, have a big positive impact on my diabetes and fat loss!

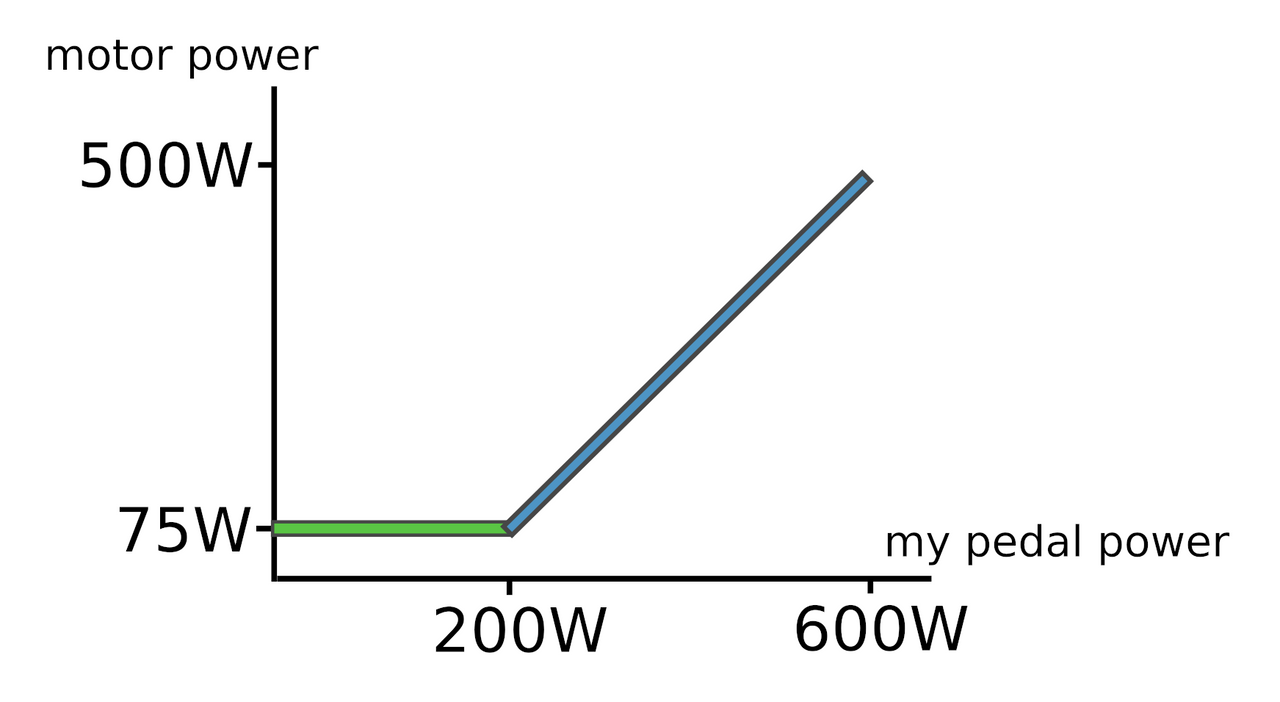

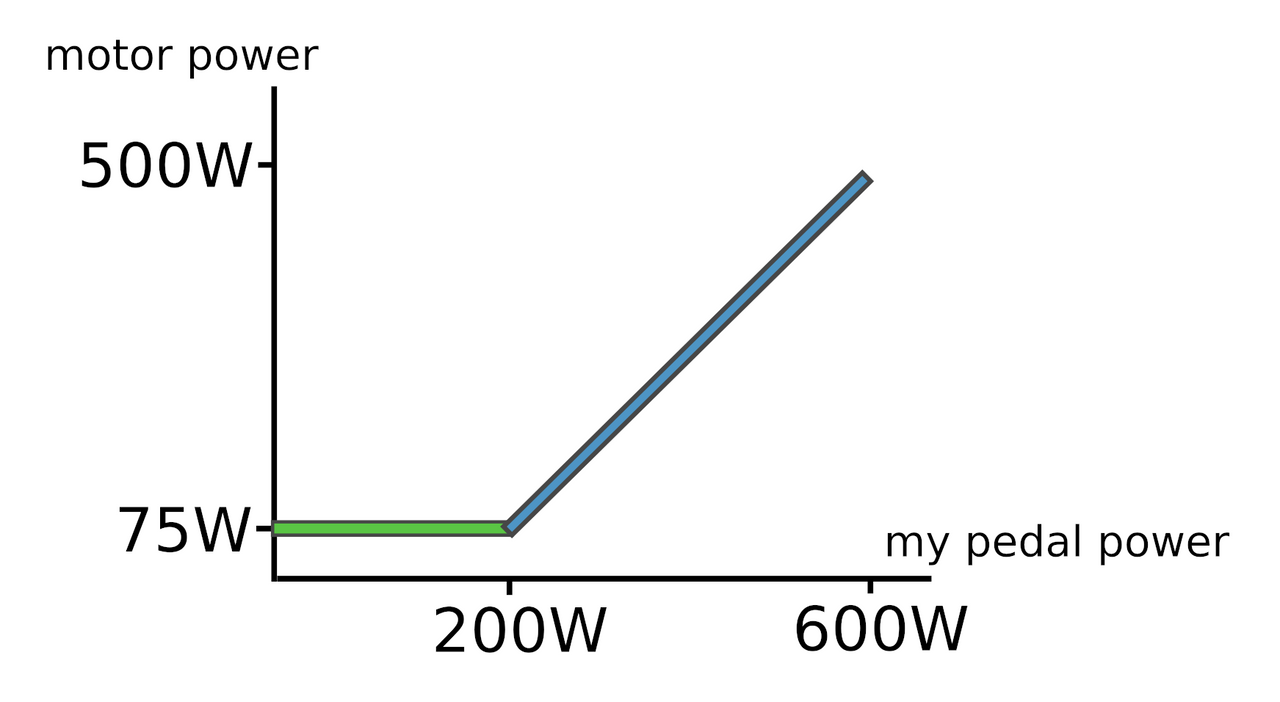

I do not like my M500 because the lowest assist level 1 is still to much for me, I wish it was way lower! But it is not only that, I wish to be force to always give my average 200W pedal power and only after that, the motor assist would turn on. See this graph:

So looking at the graph, I would like:

1.

Green line: configure a constant min value of motor power, like 75W, that is the one to compensate the the extra friction on the pedals due to the motor and extra weight on the bicycle due to the motor and battery.

2.

Green line: configure the pedal power value after which the motor would start to give assistance / motor power on top of 1., and ramp up it based on the pedal power.

This is a dream, as the original firmware does net let us configure such advanced modes. If we could develop our own firmware, we could do it. The pedal power value could be measured by the Bafang M500 torque sensor.

My power curve recorded by my pedals: