Yeah! My motor and controller came in. Not bad at all.

Boxes were heavy and protected the parts well.

Useless, to me key switch. Nice quality, but I am using my stock switch.

The throttle looks like it will work, despite the ding in one of them.

Brakes came all in one piece, prebled. I will have to take it apart to install them.

And, of course, the huge, but stout Kelly Controller. I am looking forward to setting this up:

Next the QS 205 4KW 10" hub motor. Well boxed, very well.

In perfect condition, brake rotor preinstalled.

I took a few minutes to see if the brake kit would work well, and it appears it will:

This guy struggles with it:

https://youtu.be/jzZcTjpcqiU

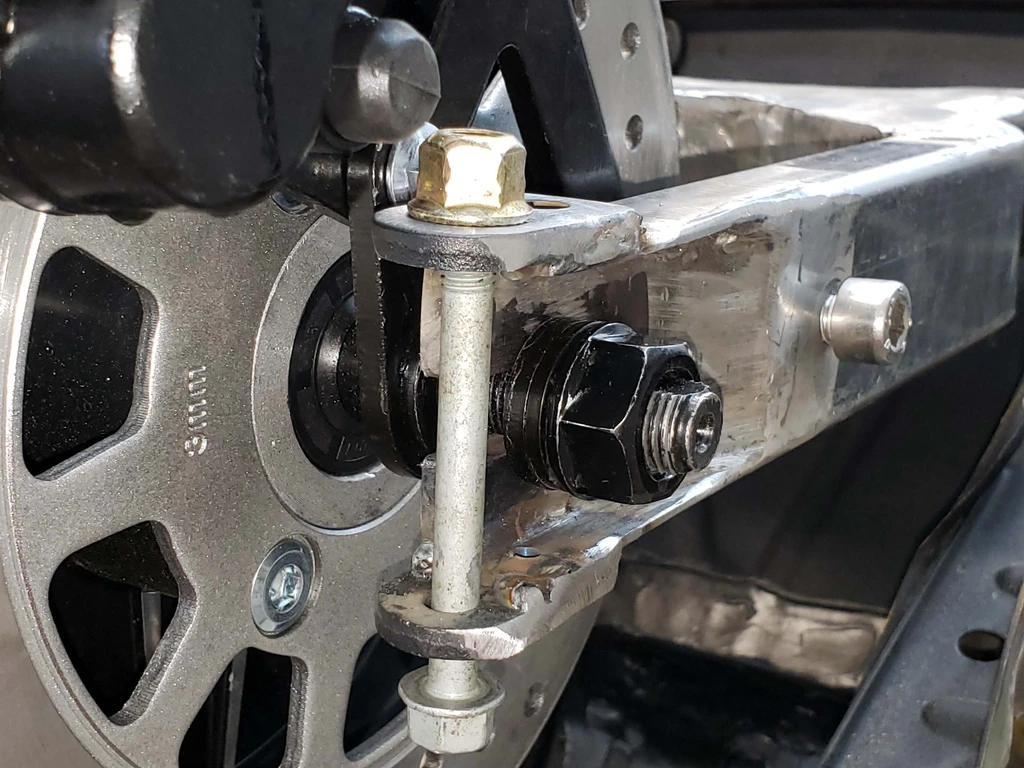

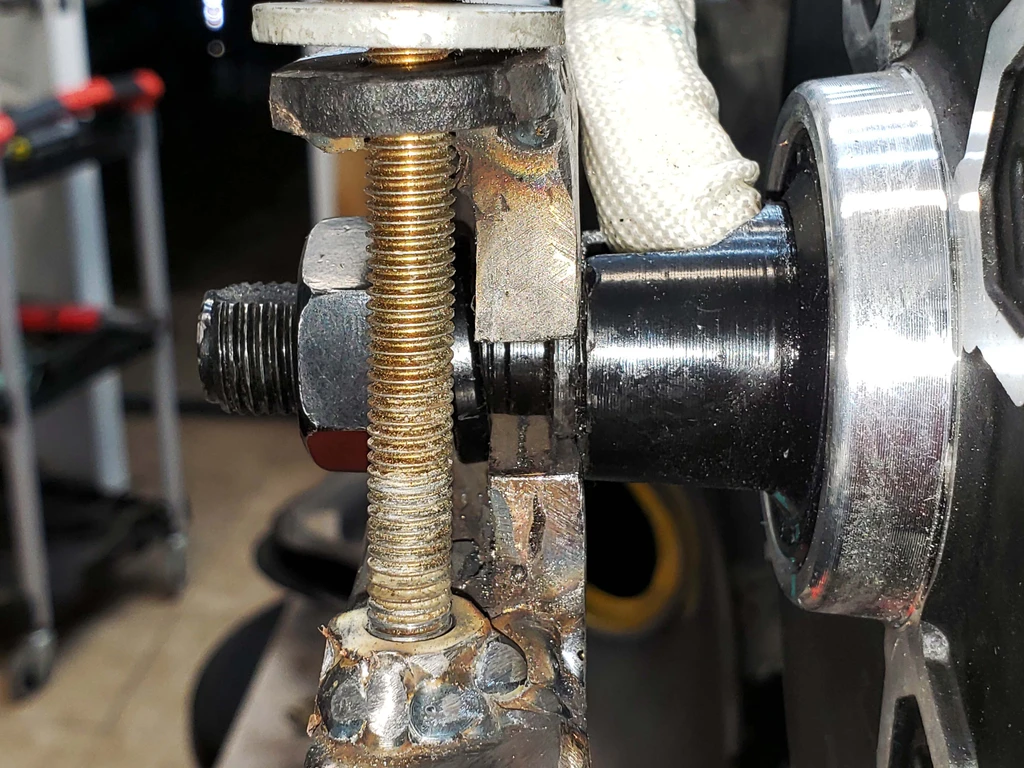

Lastly, a question: The torque arms are very loose, moving 1/4" at the tip. You can see the slot has a significant gap:

It is barely over half the thickness of my swingarm dropouts, and they are very snug, plus will be pinch bolted. Should I still use them?

If yes, is there any reason why I can't curve them to fit my swingarm, then drill and tap it for a bolt?

Anyhow, here is today's haul, plus many parts behind them. I will lay all my parts out and label them in a future post when the last remaining pieces come in.

I don't really do unboxing videos, but this guy did one. (Same guy who had trouble with the brakes.

https://youtu.be/ndclc4ZgXlA