johnybigh

10 µW

- Joined

- Feb 9, 2020

- Messages

- 6

Hello, I had problem with this Java tool. In my computer it doesn't work.

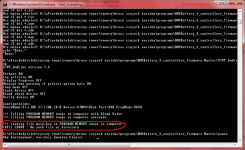

OSEC Parameter Configurator always show me this

The result of compilation via Eclipse is the same like OSEC Parameter Configurator

I have installed Java Runtime Environment, SDCC, ST Visual Development and Github repository.

Flashing via STVP work well but I don't have main.hex file.

I have flashing TSDZ2 already so this is not my first time but this Java tool make my crazy.

@edit ok problem solved. I installed everything on another computer and it work.

OSEC Parameter Configurator always show me this

>>> Loading file main.hex in PROGRAM MEMORY image in computer

(API) ERROR : No such file or directory

The result of compilation via Eclipse is the same like OSEC Parameter Configurator

I have installed Java Runtime Environment, SDCC, ST Visual Development and Github repository.

Flashing via STVP work well but I don't have main.hex file.

I have flashing TSDZ2 already so this is not my first time but this Java tool make my crazy.

@edit ok problem solved. I installed everything on another computer and it work.