And that sir is the same pattern for 7800 posts and responses.

Well.

I like to kick around different ideas. Look at it like an EV think tank. The greatest inventions in the world came from inside the human brain. someone had to think it up. Weigh the pros and cons. Then do a rough blueprint. Share it in hopes of improvement.

There is nothing stopping Tomjasz from sharing some of his e bike building secrets. How he builds his cool triangle racks or where he orders them. Exactly how his e bikes are clean factory builds. I want to know how to build at least three clean professional builds. BUT Tomjasz would rather whine how my post sucks. That sucks as he did show some of his builds and they looked great.

A push trailer is just one idea.

I like the idea of car wheels on an electric motorcycle. If enough power and good suspension highway speeds could be obtained relatively safe as what car tires are designed for. 250cc or 400cc dirt bike frame then modified for car wheels. Add the FX - 75 - 5 motor and that is my future dream ride. Waiting on Telsa batteries though as my LTOs will only last a couple miles at 90 mph.

For a push trailer though ???

If someone is just pedaling around town a couple 250W razor scooter motors will do the trick with any type of hook up. A mop handle or stick of wood. I even saw a tree branch. Only flat ground though.

Not for high speed.

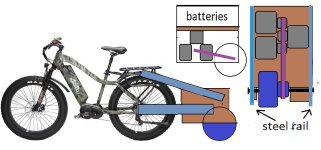

My design is basically building a two foot or 30 inch extension of the bike. Not an actual trailer. Maybe a hybrid trailer. It is basically a third wheel with steel frame work around it. Probably good for 70 pounds safely. 90 pounds would be pushing your luck. Handling with a single wheel should be great. Two wheels NOT.

Basically a powered sidecar with a 18" wheel could work but handling / steering would not be nearly as good as a small single wheel positioned behind the rear bike wheel.

I thought it up way back when I was looking at AmpFlow motors as they need gear reduction. > 5,000 rpm at 24 to 36V. Basically I was just thinking anyway possible to hook up a third 12" wheel for gear reduction. For highway speeds > 60 mph the thing should work. Kind of reminds me of a dragster. But in reverse. Not as long though. It could be a lot longer though as a single wheel will turn easily.

You could hook up about eight motors in a row and PT 2 by 6S on each side. Bolted to the steel which bolts to the bike frame like my illustration. Would need kick stands so it don't tip over until you hook it to the bike and then might need a extra large kick stand on either side of the bike. Once it gets rolling should stabilize.

I will build it close to my illustration. Short. Three brush motors , four at most. Unless I go with these motors.

https://www.youtube.com/watch?v=nH9rSwmHiy0&list=PLOEjVa2HwF1uKZ5WJsv7RsyNpkBUce_QR

I watched the video and was impressed. That is the #1 main advantage of brush vs brushless design. I do not believe that would be possible with small brushless motors. On a trailer six or eight could be possible and still not be very long. Also they do not require high voltage. Probably 24V so two old car batteries would run it on the trailer for a few miles of fun. SLAs or LIFE batteries if you wanted a daily commuter.

Another thing I noticed was the extra sprockets and short chain. All those issues of chain alignment and chain tension SOLVED.

That e bike is very impressive. Could hook up like the video then put eight more on the trailer. LTOs on the trailer and LIFEPO4s on board. Should reach highway speeds at least until the batteries die. I would invest in good tires on the e bike and the rear wheel.

I think it is an awesome idea. However I need to finish my LTO packs. It would be a great project for the three SLAs. I could build a really small experimental one. I really do NOT want to run those SLAs on top of my 12S - LIFE. Way too heavy.

The big problem is ambition. I am really lazy.

It has been at least 6 months and still working on LTO boxes.

Thanks.

LC. out.