beemac

1 kW

Hi casainho and others - first thanks for your amazing work on the tsdz2 - I hope I can contribute in some way. I've only recently got an tsdz2 and I've spent many hours getting the OS fw running - it's great.

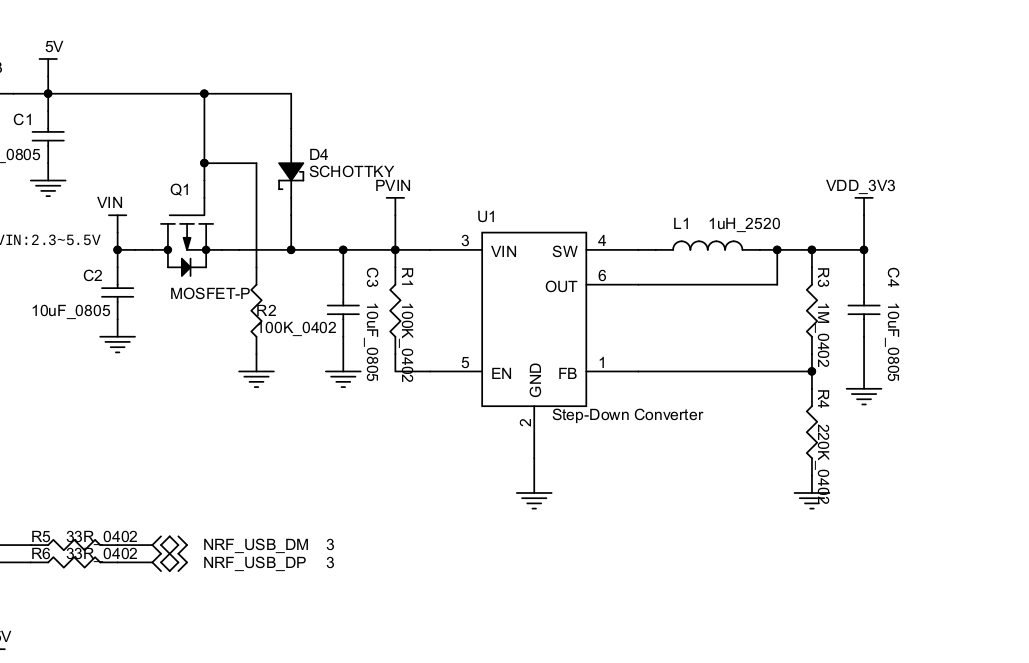

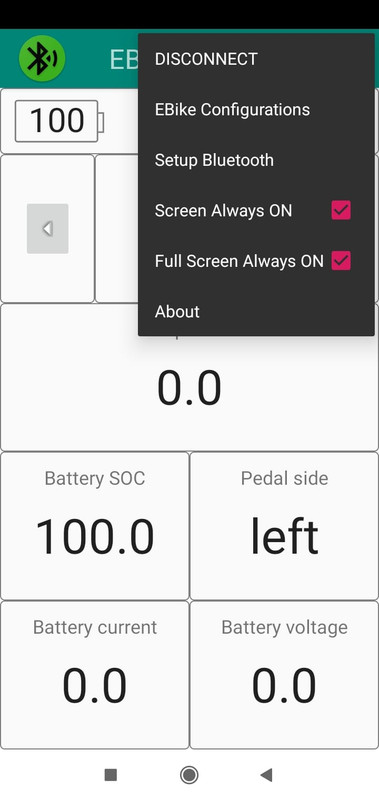

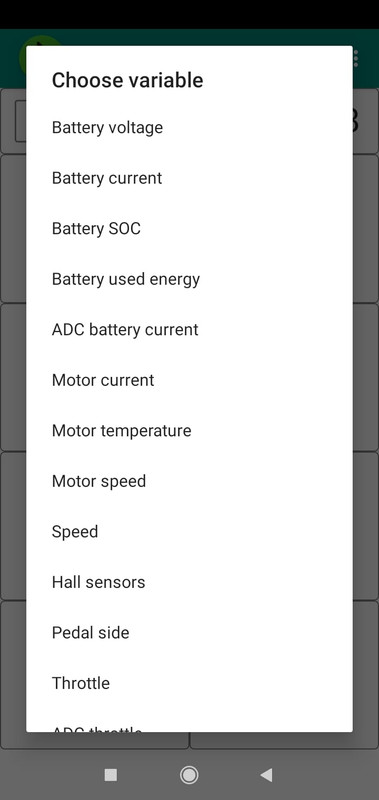

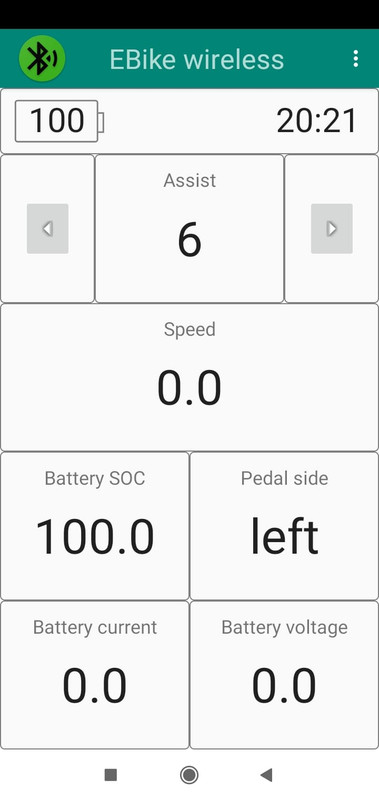

Keen to have a setup without the 860c on my handlebars and also want to help with testing early on I've built my wireless board according to the schematic here:

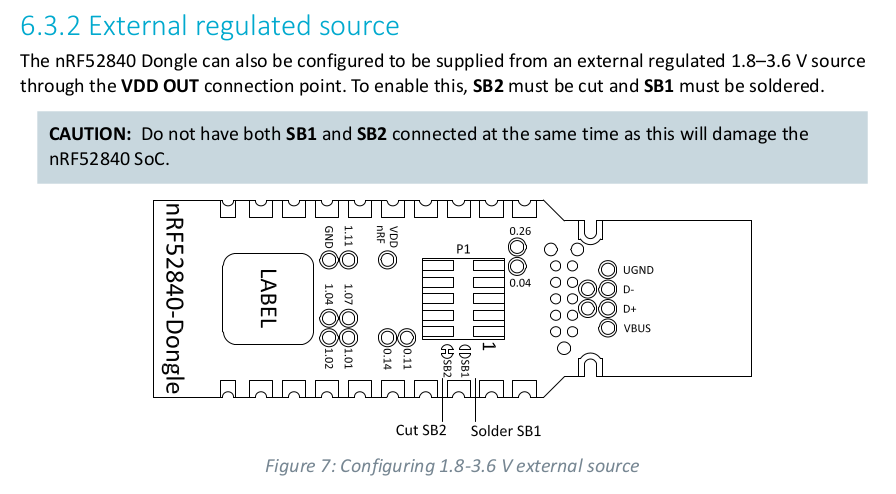

I'm using the nordic blue dongle - not the mdk. Mosfets are both Infineon brand purchased from mouser - so hoping they are genuine.

Board seems to be working ok except it doesn't switch off fully. I've got a 48v battery fully charged - so when on I get the expected 54ish volts. When off - I still get 4.9v....

The problem seems to be the BTS4140N - I've removed all other components - dc converter etc. and the mosfet just refuses to switch off completely when IN isn't (corrected!) grounded. The smaller BSS123 is working fine - but I've even removed that from the circuit to check. IN floats at the battery voltage if not grounded, so all looks good except OUT never drops below 4.9v when off...

Googling around - static damage would seem to be the obvious cause. I've replaced both mosfets taking pretty good ESD precautions - same results...

Anyone had similar issues?

Keen to have a setup without the 860c on my handlebars and also want to help with testing early on I've built my wireless board according to the schematic here:

I'm using the nordic blue dongle - not the mdk. Mosfets are both Infineon brand purchased from mouser - so hoping they are genuine.

Board seems to be working ok except it doesn't switch off fully. I've got a 48v battery fully charged - so when on I get the expected 54ish volts. When off - I still get 4.9v....

The problem seems to be the BTS4140N - I've removed all other components - dc converter etc. and the mosfet just refuses to switch off completely when IN isn't (corrected!) grounded. The smaller BSS123 is working fine - but I've even removed that from the circuit to check. IN floats at the battery voltage if not grounded, so all looks good except OUT never drops below 4.9v when off...

Googling around - static damage would seem to be the obvious cause. I've replaced both mosfets taking pretty good ESD precautions - same results...

Anyone had similar issues?