casainho said:Good to be able to disable as on some 850C/860C / users, the clock fails. On my ebike that is not happening because I am being riding at least every 2 days but my girlfriend bike, it fails as she rides sometimes once a week.Benoit said:I thought about it but I wasn't sure to implement it, or in a first time only a manual reset.

But it's a nice feature and I'll made it configurable (manual and/or auto reset with configurable amount of hours).

I saw that on the forum. Do you know why it happen ? The 850/860C has however an intagred RTC with its own battery.

casainho said:I think we should try to be consistent with buttons usage so will be easy for user to remember, leading to less frustation.Benoit said:And for the manual reset, what do you think is better : combination of pressing buttons or through a menu ?

I think a menu is less user friendly and more complex to add, except if using the current configuration menu ?

1. user must be seeing one of that variables on a custom field

2. user start customizing fields

3. user select to customize the variable he wants to reset

4. user use the same button combination for graph change x axis scale (I think is UP and DOWN simultaneous)

5. nice if the variable could fast blink for 3 seconds and just after that reset (or do no fast blink if is hard to implement)

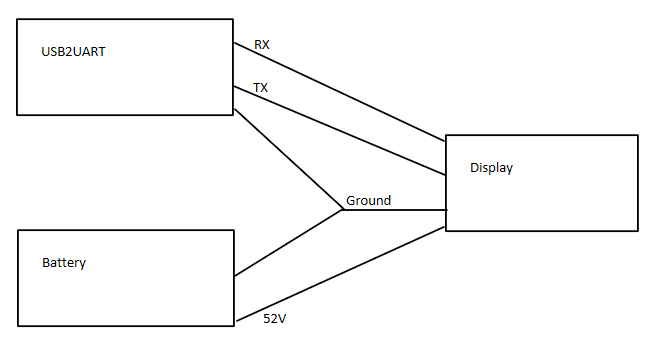

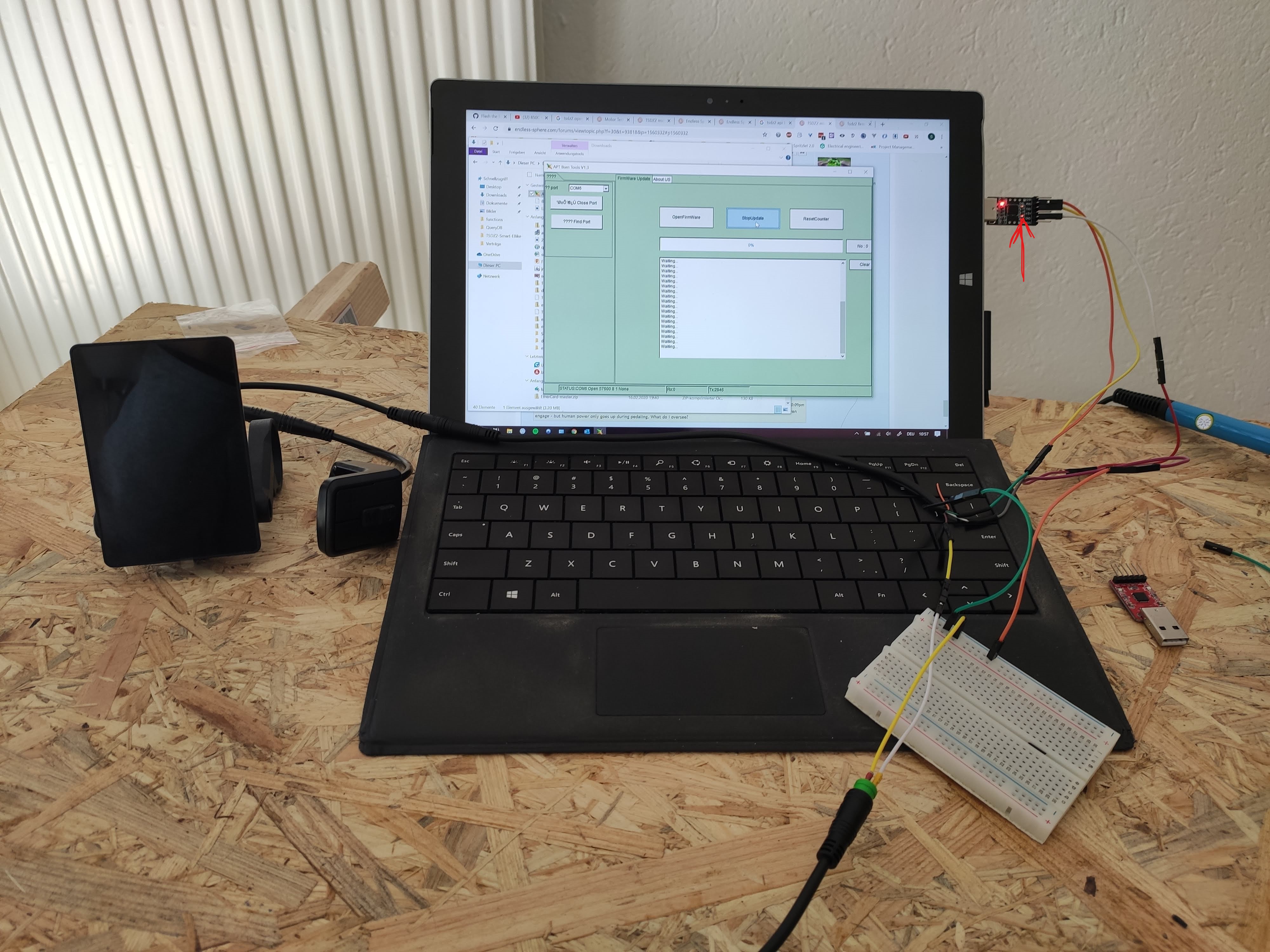

I'll see what I can do :wink: For now, as I don't use to develop in C and, in general, with low level language, it ask me lots of time and debug is not easy... modify code, compile, flash display, test... and repeat the process again until it works. I don't know if it is possible to do that better/easyer. But I'm getting there !